20年专注于精密火花机研发、生产!

提供一站式非标定制解决方案!

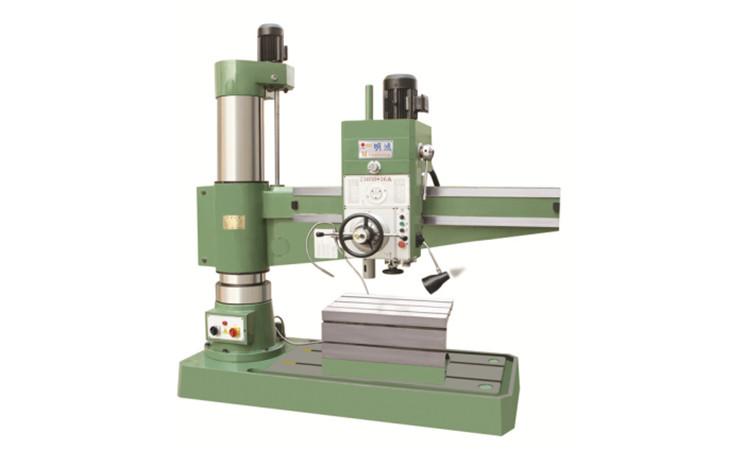

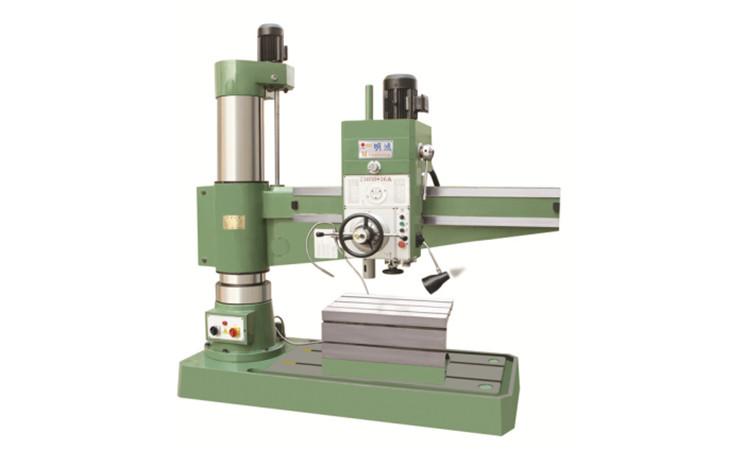

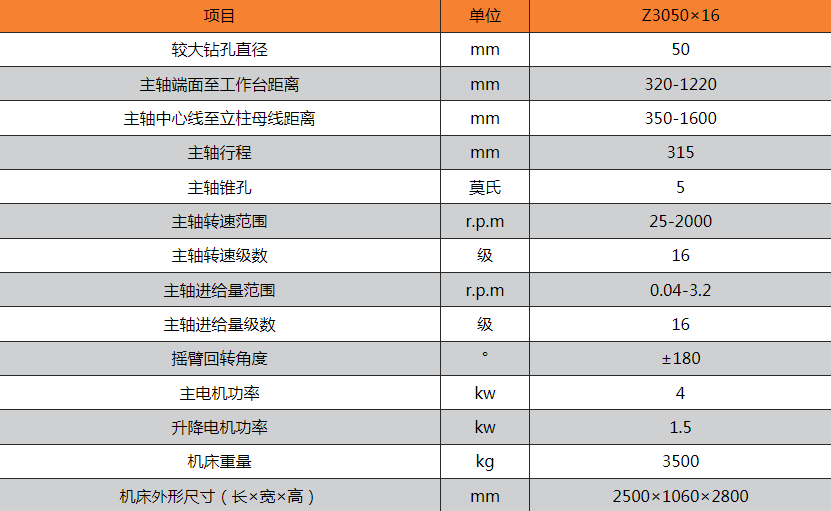

3050 radial drilling machine belongs to hydraulic radial drilling machine. It is a popular model in the series of radial drilling machines. The length of the rocker arm is 1.6m, and the drilling of 50mm can meet most processing needs. This type of radial drilling machine adopts hydraulic locking to reduce the labor intensity of operators. It has mechanical transmission and mechanical speed change. It is flexible, simple and practical to use.

The scientific and technological content of 3050 radial drilling machine is not high. The main difference in price is in product quality, i.e. the selection of raw materials. The main components such as spindle box of radial drilling machine are cast from high-strength materials and artificially aged to ensure the long-term stability of the machine tool. The tooth surface strength and toughness of forged gears are relatively good. High frequency quenching can achieve small deformation, good mechanical properties and long-term accuracy. Among various wear-resistant materials, high manganese steel is a wear-resistant steel with special properties. Ensure the product quality of radial drilling machine and provide each customer with rocker drilling machine products with high cost performance.

3050 radial drilling machine (hydraulic type) features and performance:

1. The hydraulic preselection speed change mechanism can save a lot of auxiliary processing time.

2. Spindle forward and reverse, parking, speed change, neutral and other operations, controlled by a single handle, flexible and simple.

3. The spindle box, rocker arm and inner and outer columns adopt the diamond block structure driven by hydraulic pressure, and the clamping is reliable.

4. The surface of rocker arm guide rail, outer column, main shaft, main shaft sleeve and inner and outer column rotation track shall be quenched.

5. There are perfect safety protection devices and external column protection.

6. In terms of structural design, effective measures are taken to make the accuracy of the machine tool and the use of the whole machine more humanized.

ZNC 是手摇火花机: X、Y轴没有装马达,工作时需要人工手摇;电箱不具有自动移位功能,是一款手动操作的火花机。PNC是半自动火花机,X、Y轴都有马达装置,工作时是可以自动按程序设定的轨迹行走,不用人工手摇,这样可以省很多人力;电箱没有自动移位功能,是一款半自动火花机。CNC是全自动火花机,X、Y轴···